Unlocking Potential: Aftermarket Components as a Cost-Effective Remedy for Equipment and Heavy Equipment

In the ever-evolving landscape of equipment and heavy equipment maintenance, the usage of aftermarket components has arised as an engaging different worth discovering. These components, usually forgotten for original equipment producer (OEM) parts, offer a cost-effective remedy that necessitates focus. While the principle might raise eyebrows among reactionaries, the advantages that aftermarket parts provide in terms of expense financial savings, top quality, and efficiency are not to be underestimated. As industries look for methods to maximize and optimize procedures effectiveness, the possible unlocked by aftermarket parts positions fascinating opportunities that might reshape recognized practices and generate substantial advantages.

Price Savings and Value Suggestion

The cost financial savings and value proposition of using aftermarket components for machinery and heavy tools are significant factors that contribute to operational efficiency and monetary stability in various markets. By deciding for aftermarket parts over original devices supplier (OEM) components, businesses can realize substantial price financial savings without compromising on quality or performance. Aftermarket parts are typically a lot more competitively priced than their OEM equivalents, enabling firms to lower repair and maintenance expenditures while still making certain the proper functioning of their machinery and devices.

Furthermore, the worth recommendation of aftermarket parts extends beyond price savings. These components are commonly offered and use a wider choice compared to OEM components, providing businesses with greater versatility and ease in sourcing the parts they require. Furthermore, aftermarket parts are understood for their excellent quality and integrity, meeting and even exceeding industry criteria oftentimes. This dependability translates into improved operational efficiency and lowered downtime, inevitably boosting overall performance and success for companies that choose to leverage aftermarket options for their equipment and heavy equipment demands.

Quality and Compatibility Guarantee

When considering the utilization of aftermarket parts for equipment and heavy equipment,Highlighting the extremely important significance of high quality control and compatibility verification is crucial. Making certain that aftermarket components exceed or fulfill market standards for quality is vital to keeping the ideal efficiency and durability of the equipment. Quality guarantee procedures, such as strenuous screening treatments and accreditations, give confidence to devices proprietors that the aftermarket parts will certainly operate reliably and efficiently.

Increased Schedule and Choices

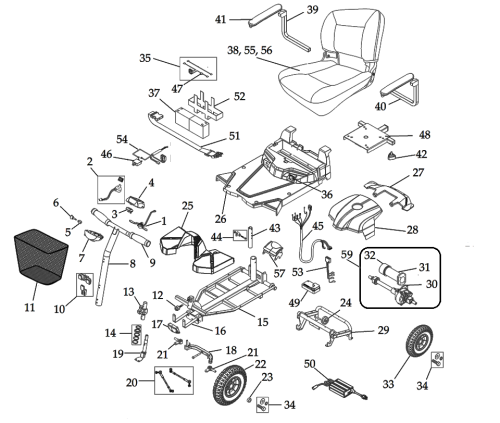

With an expanding market and expanding need, aftermarket components for machinery and heavy tools are now providing increased schedule and a wider series of options to accommodate the varied demands of devices owners. This surge in schedule is driven by the aftermarket components industry's dedication to meeting the details demands of various machinery brands and models. Tools owners can now access a broad selection of aftermarket parts, ranging from engine elements to hydraulic parts, electric systems, undercarriage parts, and extra.

Furthermore, aftermarket components producers are continually broadening their product to include components for a wider range of machinery and hefty equipment, making certain that owners can discover ideal replacements despite the equipment type or version they possess. This enhanced schedule and variety of aftermarket parts equip tools owners to make cost-efficient decisions without jeopardizing on high quality or efficiency. Therefore, they can efficiently keep, fix, and upgrade their machinery with confidence, recognizing that aftermarket components offer a trustworthy alternative to OEM parts.

Efficiency and Resilience Perks

Enhancing equipment and hefty tools with aftermarket parts brings noteworthy performance and resilience advantages to tools proprietors. Aftermarket components are frequently developed with improvements in modern technology and products, offering improved efficiency contrasted to initial tools supplier (OEM) components. Updated parts can cause raised power, performance, and total equipment capacities, bring about boosted performance and functional efficiency.

Additionally, aftermarket parts are frequently engineered to be a lot more resilient and resilient than their OEM counterparts. This enhanced longevity can translate to lowered downtime for upkeep and fixings, eventually saving devices owners valuable money and time. By buying aftermarket parts known for their robustness, equipment and hefty tools can stand up to extreme operating conditions and hefty workloads with greater strength.

In essence, the performance and durability advantages of aftermarket components contribute significantly to maximizing the performance and long life of machinery and heavy equipment. Equipment owners stand to obtain an affordable edge by leveraging aftermarket options to improve the her latest blog overall performance and resilience of their properties.

Sustainability and Ecological Influence

The use of aftermarket components not just enhances the performance and durability of machinery and heavy equipment yet also plays an essential function in resolving sustainability concerns and minimizing environmental impact. By selecting aftermarket components, sectors add to the reduction of waste generation considering that these components are frequently sourced from recycled materials or with remanufacturing processes. This method lines up with the concepts of a round economic climate, where resources are used successfully, and waste is reduced.

Additionally, aftermarket parts can extend the life-span of equipment and equipment, reducing the regularity of substitutes and consequently lowering the general carbon footprint associated with making new machinery. In addition, the production of aftermarket parts usually includes much less energy Discover More Here consumption and less discharges contrasted to producing original tools producer (OEM) components.

Conclusion

In verdict, aftermarket components provide an affordable remedy for equipment and heavy tools by giving cost savings, top quality assurance, increased schedule, performance benefits, and sustainability advantages. These components not only offer a feasible alternative to original tools supplier parts yet likewise add to the overall performance and longevity of equipment and equipment. Accepting aftermarket components can result in substantial cost financial savings and boosted performance, making them a useful alternative for services aiming to maximize their resources.

By deciding for aftermarket components over original devices supplier (OEM) parts, companies can recognize significant price savings without endangering on top quality or performance (Bobcat Aftermarket Parts). Devices owners can currently access a vast selection of aftermarket parts, varying from engine parts to hydraulic components, electric systems, undercarriage components, and much more

Additionally, aftermarket components suppliers are constantly expanding their product lines to consist of components for a more comprehensive array of equipment and hefty site here tools, ensuring that owners can find appropriate substitutes no matter of the devices kind or version they have. Aftermarket components are often developed with improvements in modern technology and products, offering boosted efficiency contrasted to original equipment producer (OEM) parts. Additionally, the production of aftermarket parts frequently includes much less energy usage and less emissions contrasted to producing original equipment producer (OEM) components.